Material

95% Alumina Ceramic Beads is manufactured by dry press method and is sintered at temperature up to 1700°C. It enjoys high temperature resistance, excellent insulating property, and efficient thermal conductivity and heat transfer. Thanks to its excellent characteristics, the ceramic beads is widely used as components of ceramic heating pad at operation of pre- and post-weld heat treatment, welding process, stress-relieving, ship-building, other heat-resistance-environment.

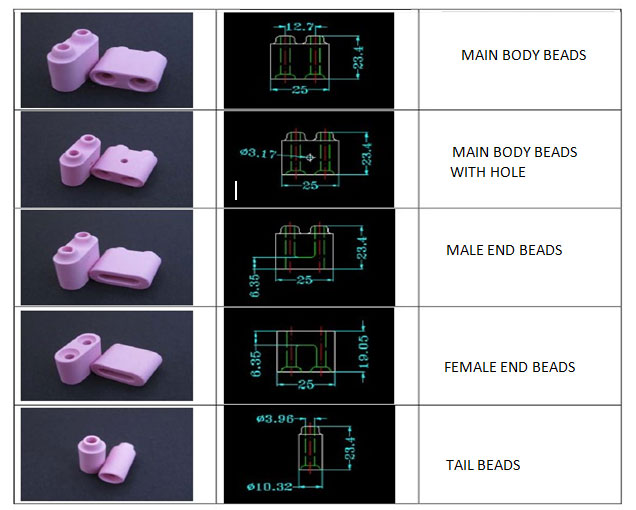

Other Shapes Available:

*Available in Pink and White color

Material Data Sheet:

| Properties | Unit | Value |

| Alumina Content | (m/m) % | 95% |

| Bulk density | g/cm3 | 3.65-3.70 |

| Grain Size | Um | 6 |

| Compressive strength | MPa | 1800 |

| Flexural strength | MPa | 280 |

| Vickers Hardness | Hv 10 | min. 1100 |

| Young’s Modulus | GPa | 300 |

| Thermal Conductivity (20-100°C) | W/m*K | 16 – 24 |

| Specific Heat | J/kg*K | 700 – 850 |

| Electric strength | KV/mm | 10 |